Molding machine

Classification:

Key words:

Yuanbang Machinery

Summary:

Specializing in the production of casting sand processing equipment/sand recovery system/metal smelting equipment/shot blasting machine/full set of automatic molding line equipment

Product Details

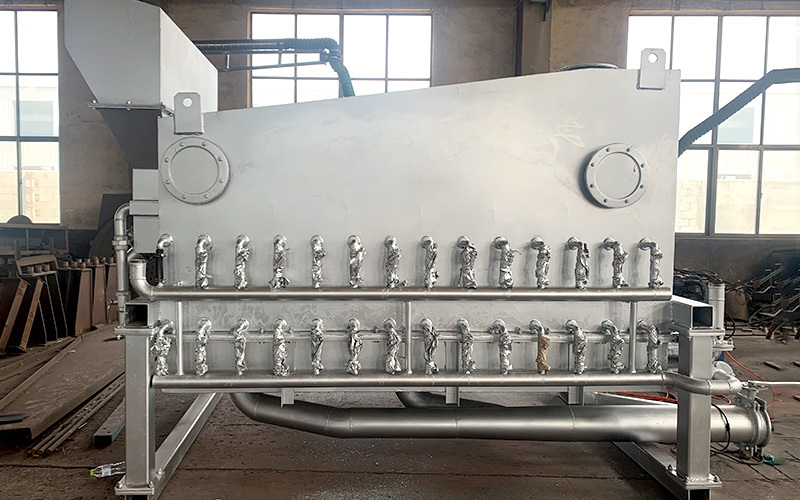

Product Description

1、Full-automatic one-button operation, no need for professional workers

2、Horizontal parting, convenient for core laying.

3, casting hardness: casting hardness can be freely adjusted according to the requirements of different castings, only a few parameters need to be adjusted, very convenient and rapid, can reach 85-90 degrees.

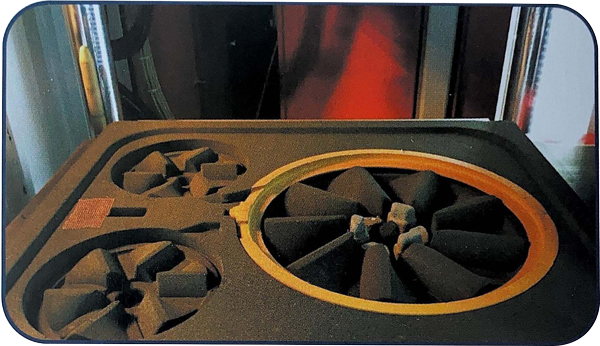

4, casting height adjustable, saving sand: the upper and lower compaction plate can be adjusted, so as to produce different casting height.

5、Casting quality is constant and uniform: this machine adopts high-precision mechanical positioning system, microcomputer, position detection linkage, the whole molding process is fully automatic control, no need for human intervention, so the quality of molding is stable, uniform, efficient and reliable.

6、Equipped with safety protection devices: advanced light curtain protection to ensure the personal safety of the operator.

Easy to core

Production of complex assemblies

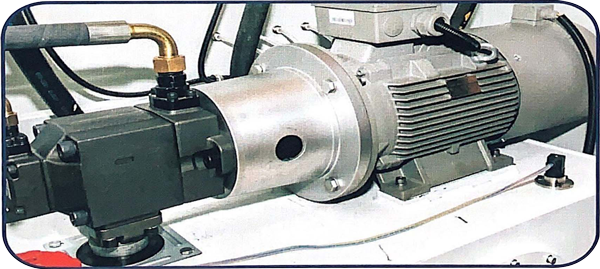

Hydraulic power

Smooth movement

Higher compaction

Adjustable mold height to save sand

24-hour continuous smooth operation

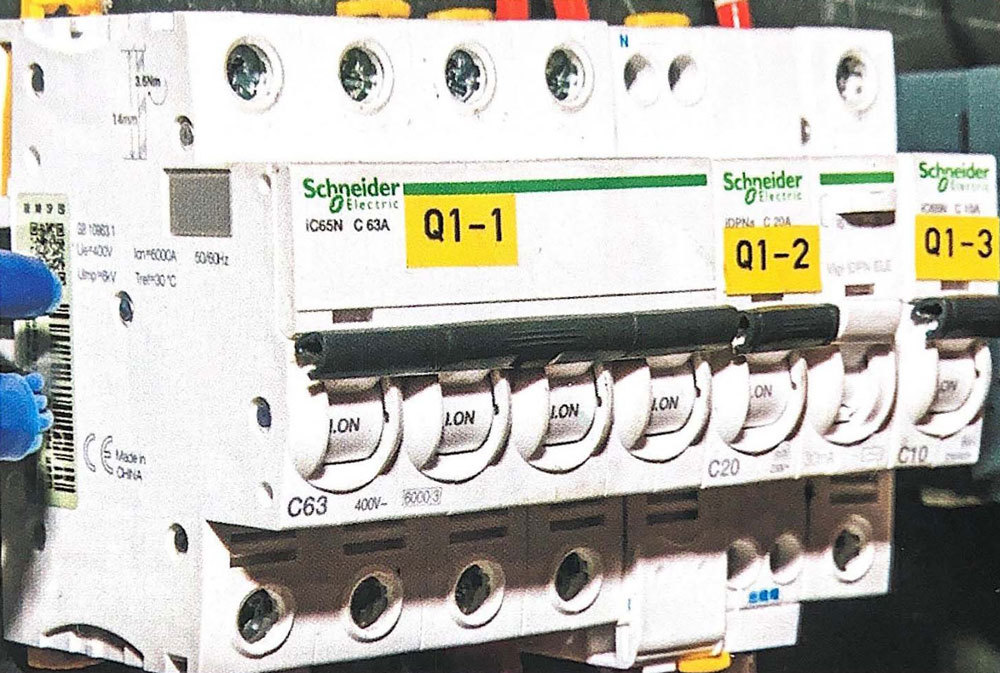

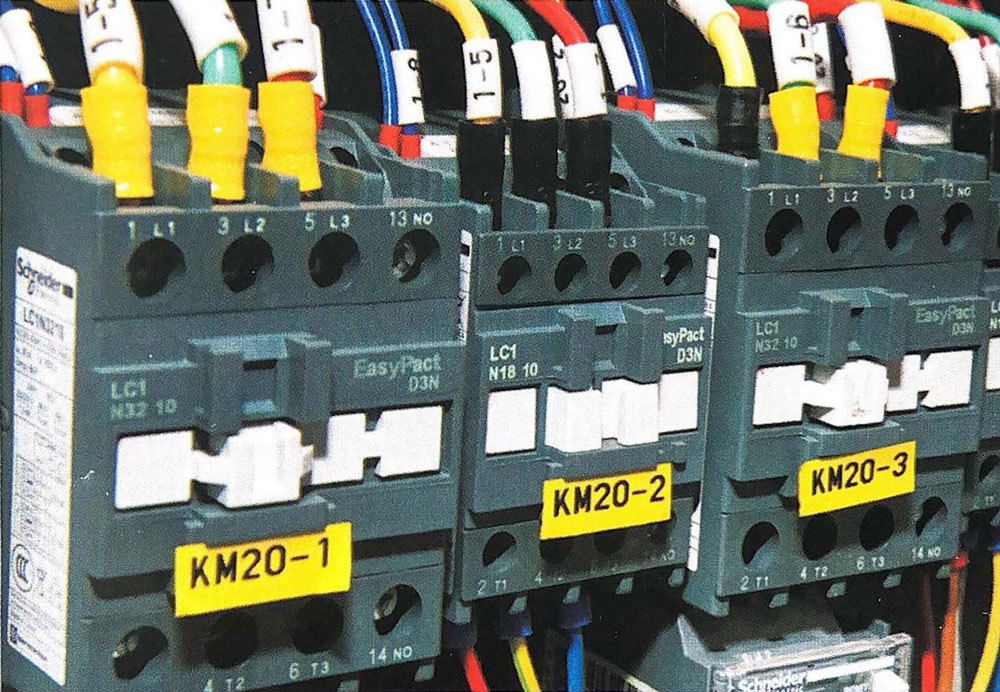

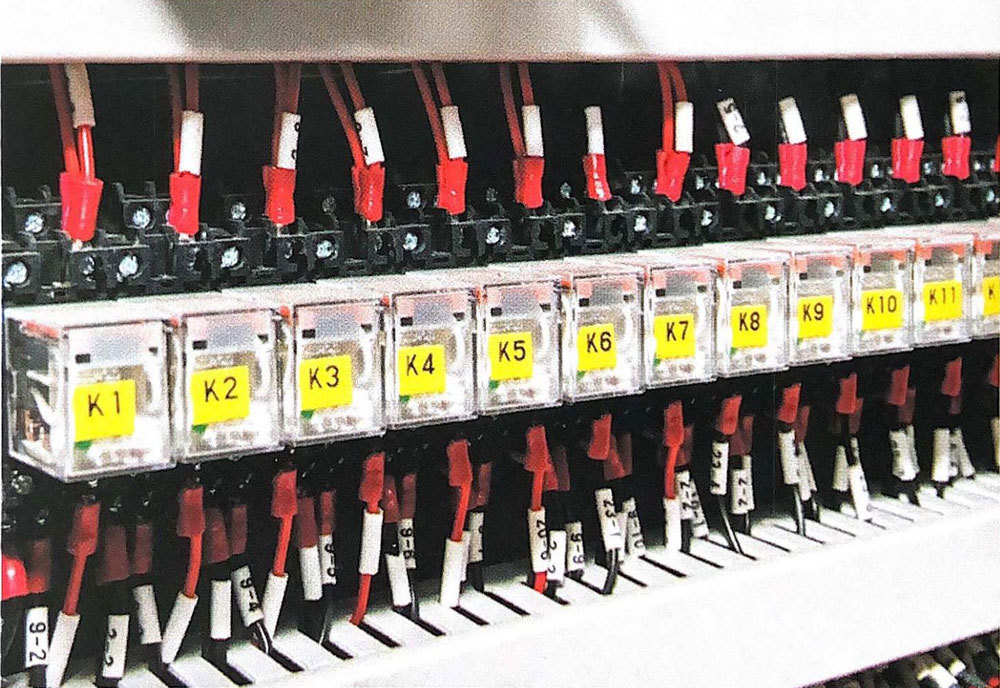

| Electronic System All electrical components are well-known brands such as French Schneider air switch/AC contactor/thermal protector, etc. |

|

|

|

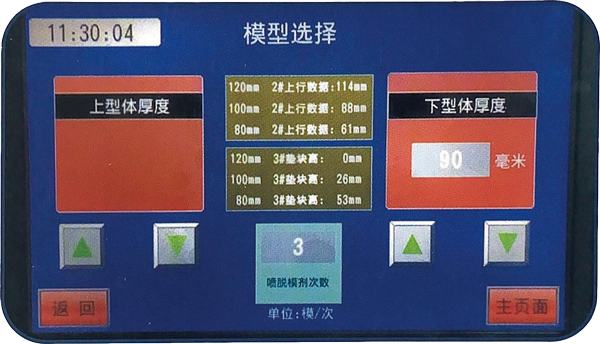

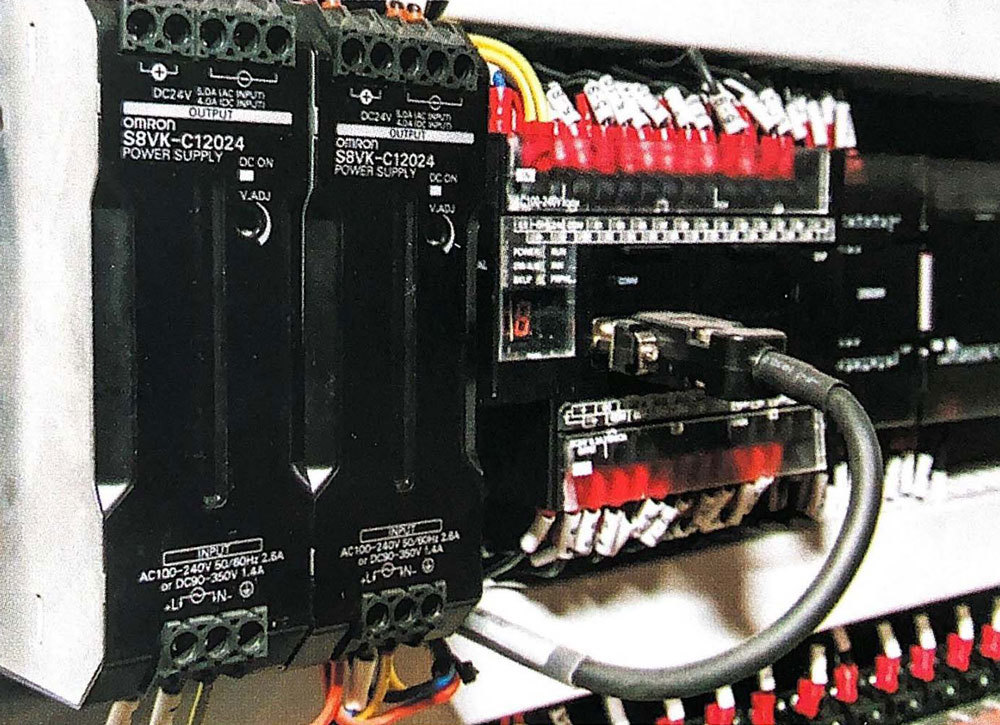

| Control System Japan Omron PLC, 10-inch multi-touch screen, safety encoder |

|

|

|

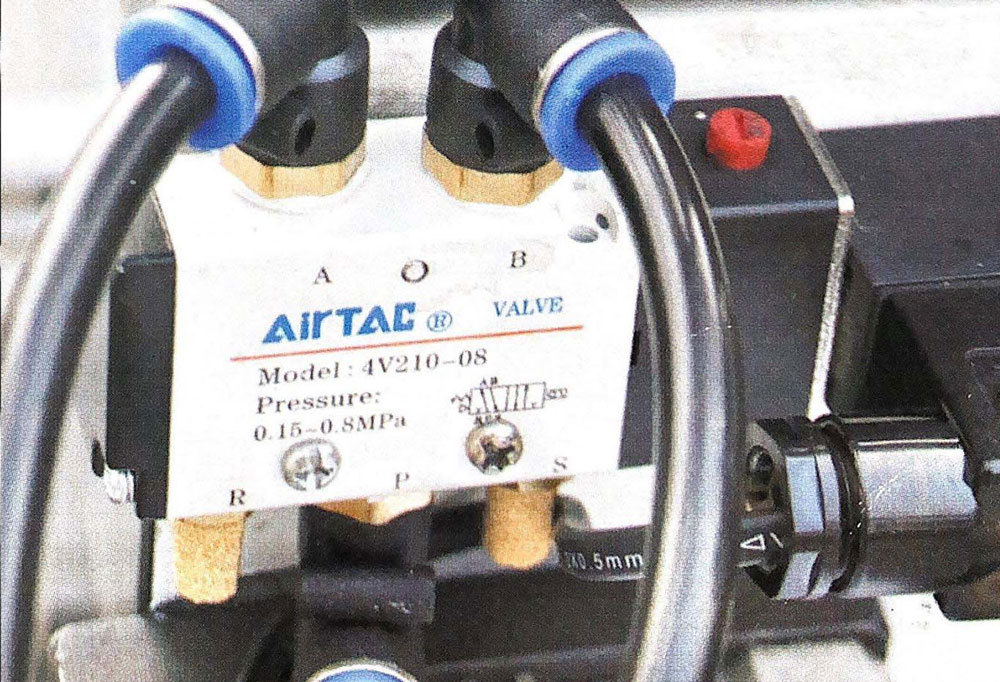

| Pneumatic System Airtac cylinders/solenoid valves/pneumatic components from Taiwan |

|

|

|

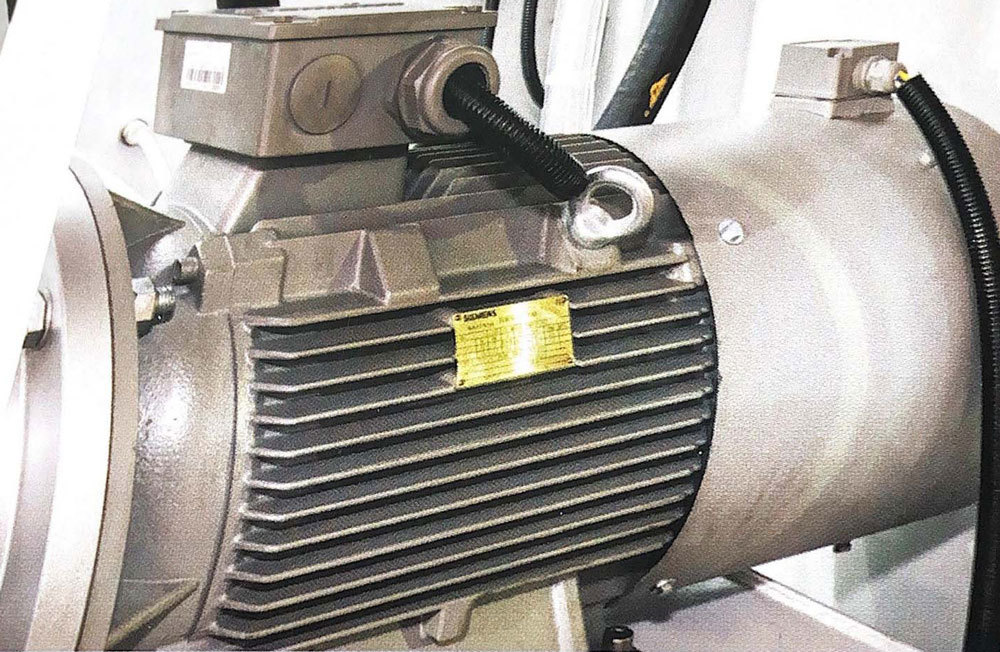

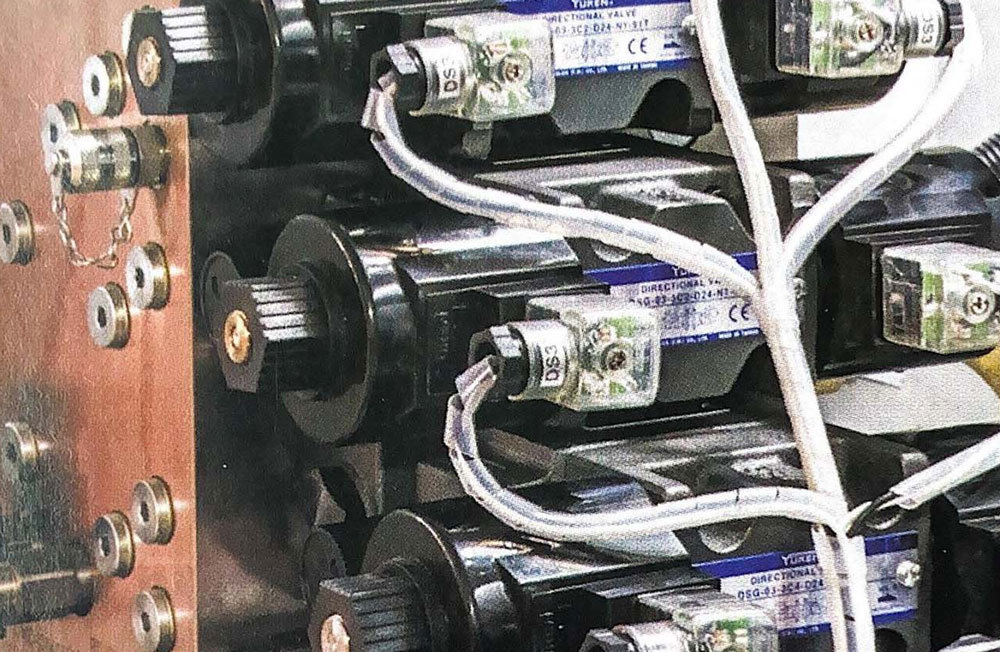

| Hydraulic system Adopting Japan Yuken hydraulic valves and oil pumps, Germany Siemens frequency conversion motor |

|

|

|

Main technical parameters

| Typology | Z-Y4252 | Z-Y4555 | Z-Y5161 | Z-Y6171 |

| Sand box size (mm) | 420*520 | 450*550 | 510*610 | 610*710 |

|

Sand mold height Numerical control |

(Top)80~170 (Bottom)80~150 |

(Top)100~200 (Bottom)100~200 |

(Top)100~180 (Bottom)100~180 |

(Top)100~180 (Bottom)100~180 |

| Modeling methodology | Air Blast + Hydraulic Extrusion | |||

| Modeling speed (excluding time to put in core) |

35 seconds/mold 100 molds/hour |

38 seconds/mold 95 molds/hour |

41 seconds/mold 90 molds/hour |

45 seconds/mold 85 molds/hour |

| Air consumption for sand blasting | 1.1m³ | 1.1m³ | 1.2m³ | 1.3m³ |

| Extruder | 0.6Mpa | 0.6Mpa | 0.7Mpa | 0.7Mpa |

| Driving mode | Pneumatic, pneumatic and hydraulic devices | |||

| Input Voltage | AC220V~380V | |||

| Input Voltage | 11KW | 11KW | 15KW | 18.5KW |

| Sand mold weight | 100KGS | 130KGS | 180KGS | 250KGS |

| Net weight of the machine | 8T | 8.5T | 9.5T | 10.5T |

| Control mode | Touch Screen/PLC | |||

| Number of castings | 15 | 21 | 21 | 25 |

| Pneumatic | 0.55~0.75Mpa | |||

| Mould Type | Double-sided aluminum plate | |||

| Casting diameter | o30、040 | |||

| Sand Shooting Method | 3 levels of adjustment | |||

Product process flow

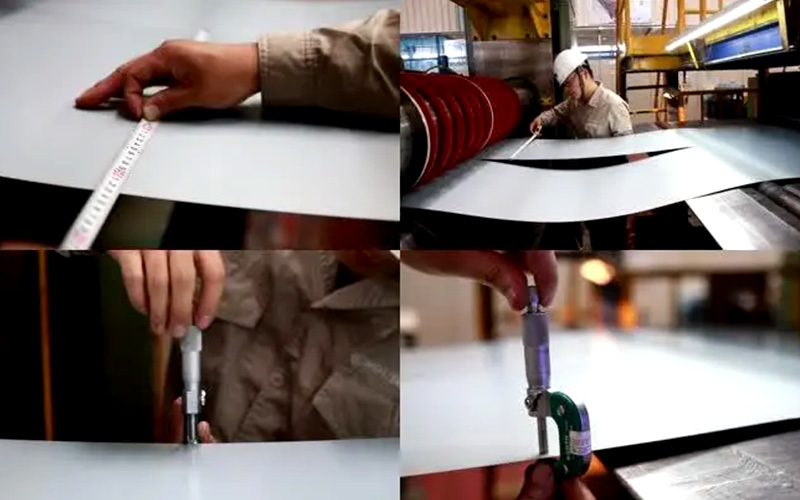

Incoming inspection

01

Cutting

02

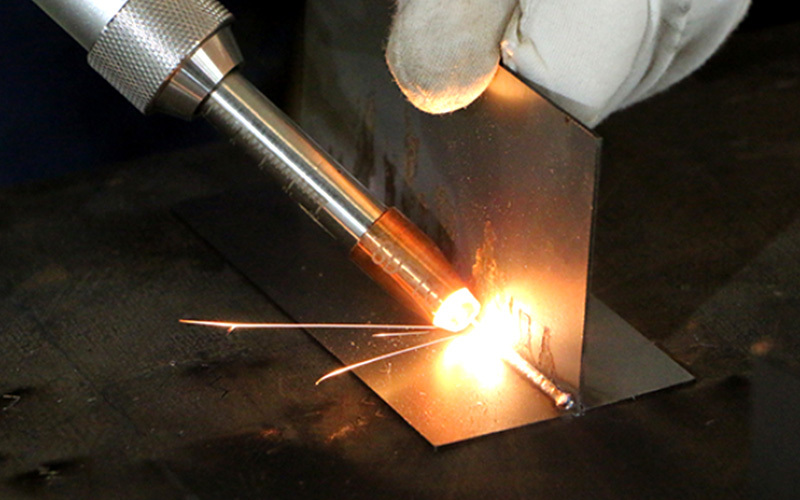

Welding

03

fine machining

04

Assembly

05

Initial debugging

06

Spraying

07

Packaging

08

engineering case

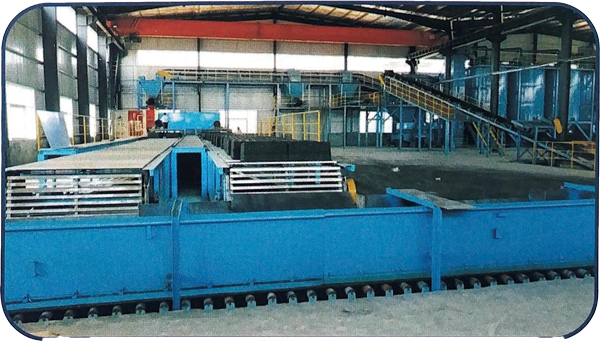

Self-hardening resin sand sand treatment production line

China Yituo (Luoyang) Steel Casting Plant 120t-h Clay Sand Production Line

Rizhao Hongguan Machinery

Henan Zhongao Machinery 100t-h Clay Sand Production Line

V method, lost form production line

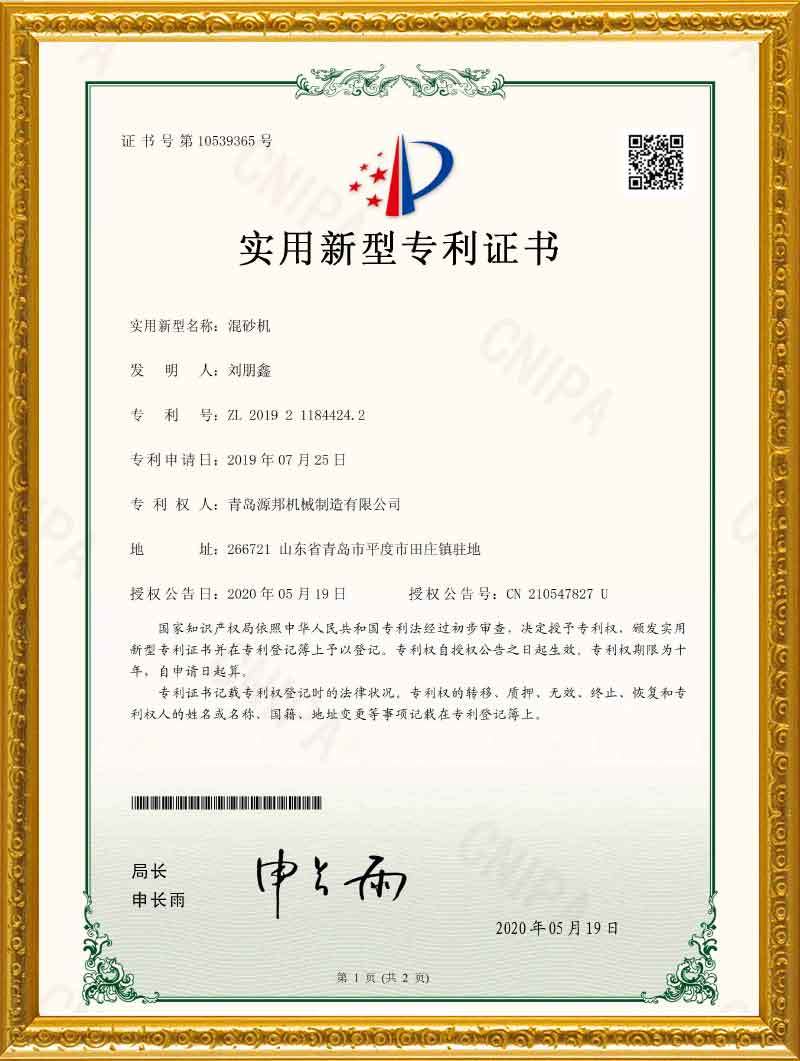

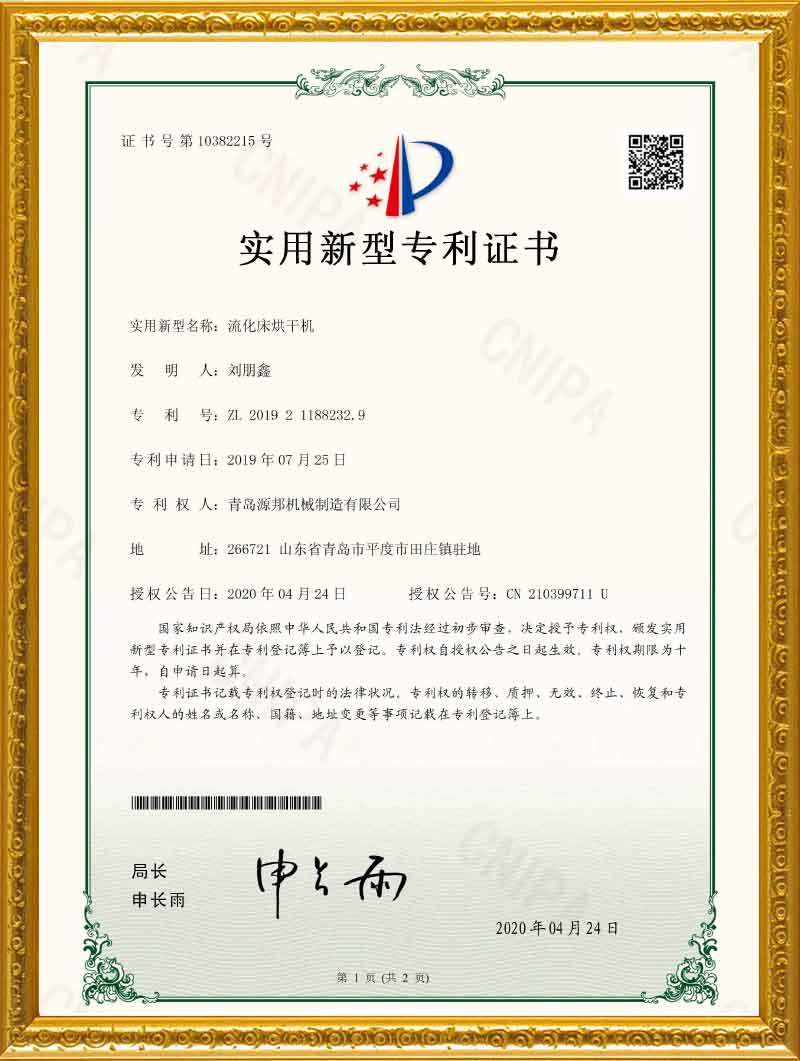

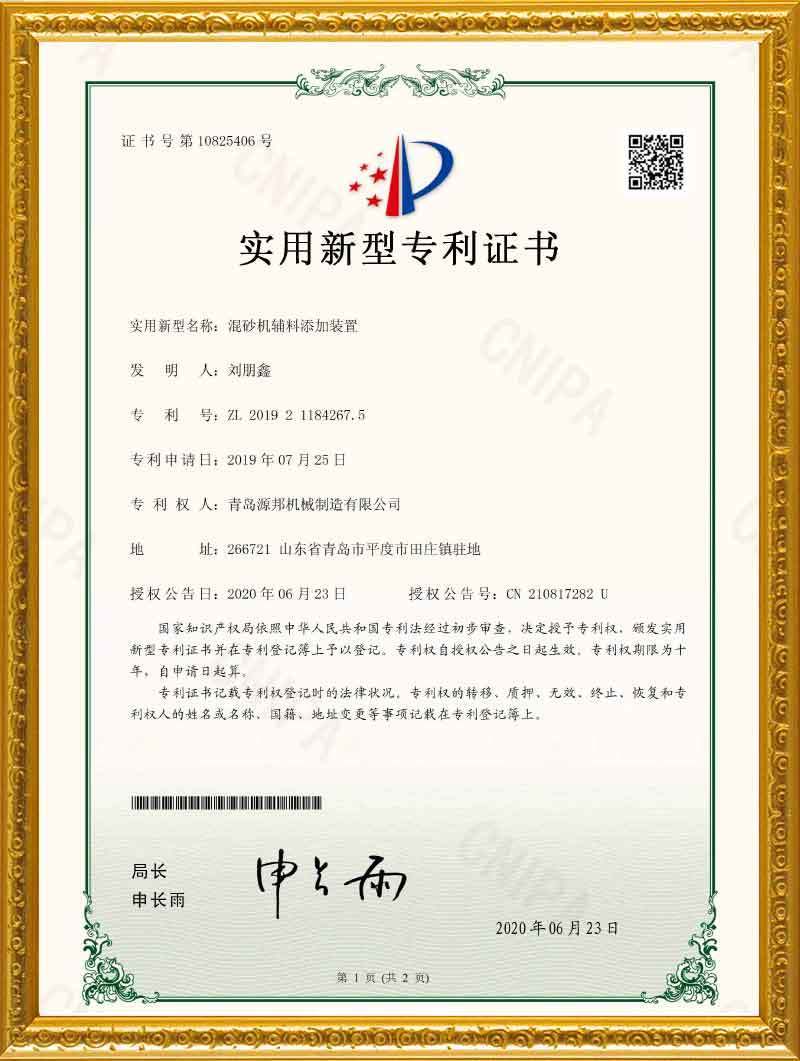

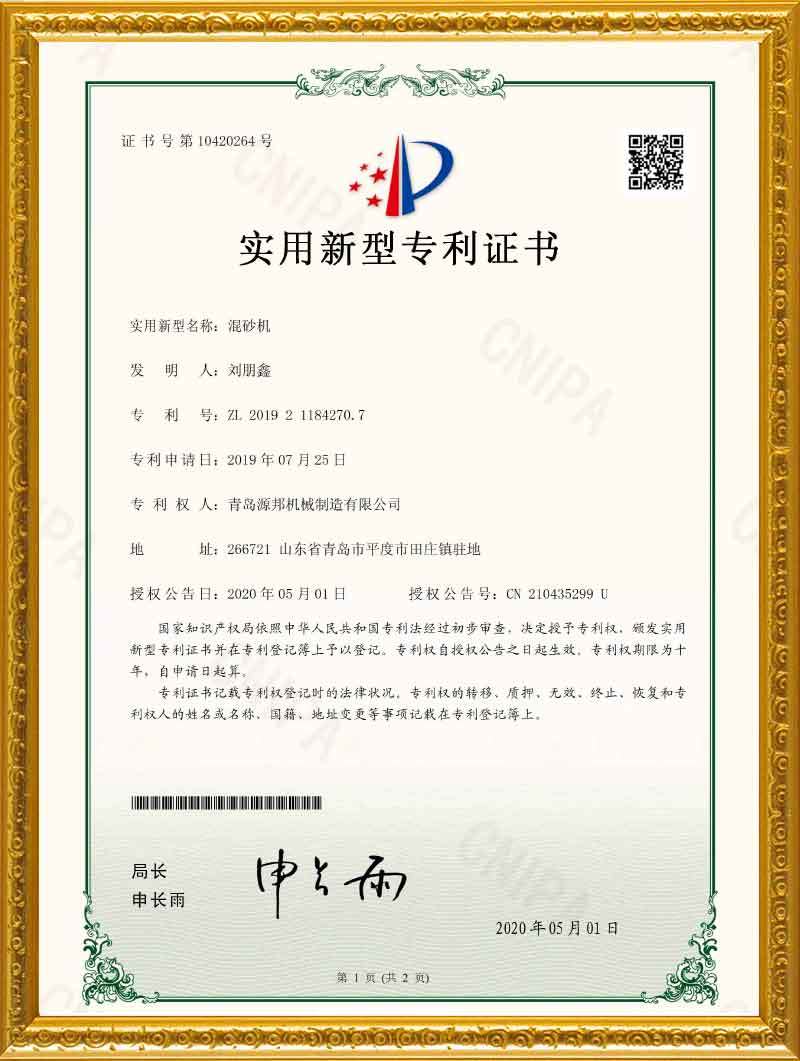

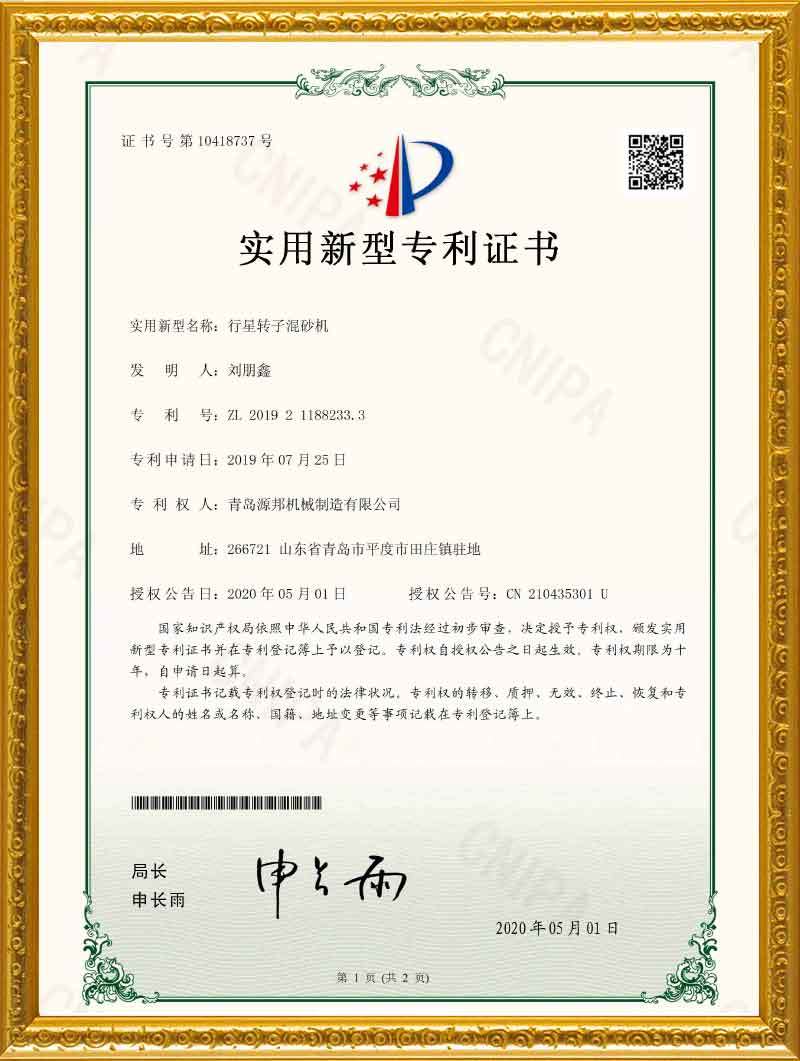

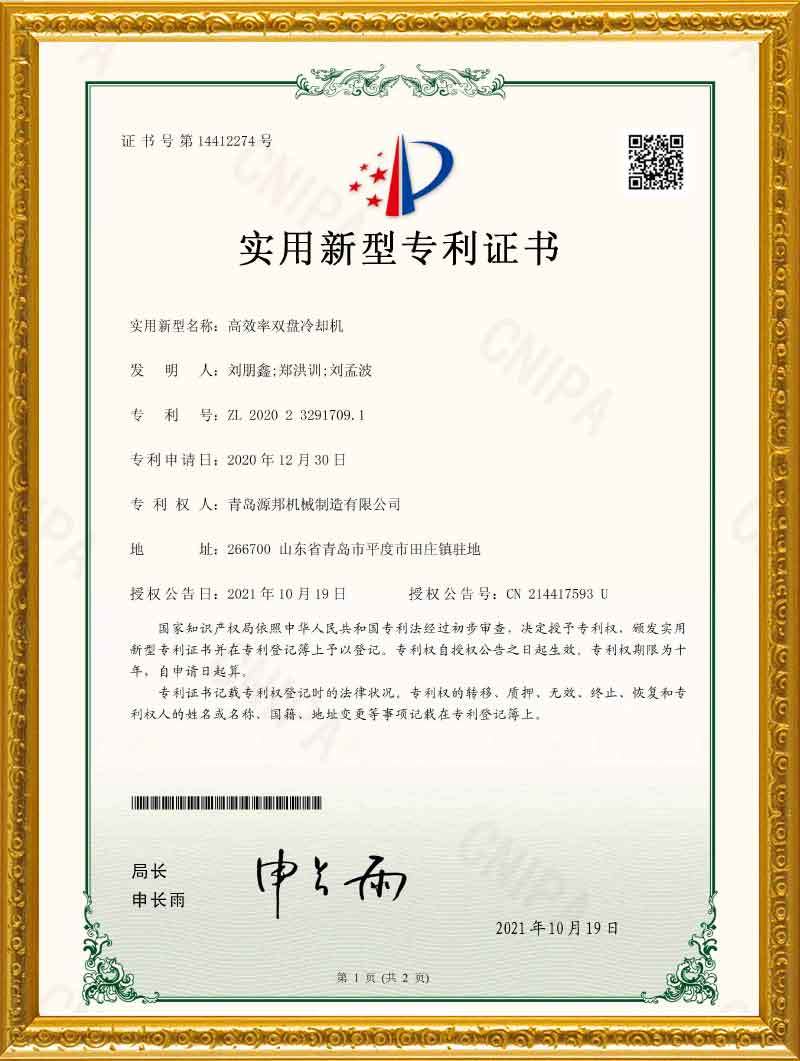

Honor

Related Products

2020/07/16

2020/07/23

2020/07/16

2020/07/16

SL Series Ebullated Cooling Bed Equipment

2020/07/16

S43 Series Fine Hexagon Sand Sieving Machine

2020/07/16

L32 Series Falling Sand Cooling Drum

2020/07/16

2020/07/16

Listen and provide trusted solutions.