Core making machine

Classification:

Key words:

Yuanbang Machinery

Summary:

Specializing in the production of casting sand processing equipment/sand recovery system/metal smelting equipment/shot blasting machine/full set of automatic molding line equipment

Product Details

Product Description

The automatic vertical parting cold box core shooting machine is a high-efficiency core-making machine dedicated to valves, gearboxes, bearing chambers, boxes, and half-pipe sand cores. The machine has compact structure, convenient operation, and rapid action. Stable, long service life, low maintenance rate, etc. This machine adopts high-rigidity four-column frame structure. The horizontal moving car of sand barrel and blowing plate adopts bracket roller and side wheel guide structure, which operates fast and smoothly (no impact phenomenon of suspension structure); The vertical movement of sand barrel and blowing plate adopts four-axis guide, with high positioning accuracy and good sealing effect of joint surface. The vertical movement guide of worktable adopts thickened high-rigidity guide column, with high mold clamping accuracy, rapid acceleration and deceleration function of sand shooting cylinder and sand shooting head. The machine is equipped with an advanced YL-30A type full-automatic triethylamine gas generator. Its various process parameters can be set and modified on the display screen of the core launcher without regulating the internal components of the generator, thus eliminating potential safety hazards in control. The generator adopts high-efficiency explosion-proof heater, imported electric proportional valve, large flow pilot valve, non-pressure amine atomizing pump and other devices, which can realize automatic control of the whole process of triethylamine quantitative atomization and amine addition, heating, gasification, amine blowing and cleaning, the sand core can be completely cured in a few seconds, and the amount of amine used is very low. Under ideal conditions, the amount of amine used per ton of sand core is only 1-2L. The whole machine control adopts PLC program control, man-machine interface parameter setting, can realize the equipment automatic, manual, inching and automatic cycle four operation modes.

Technical parameters

| Product Model | M-YLA | M-YLC | M-YLD |

| Amount of sand (L) | 20~150 | 20~150 | 30~500 |

| Sand area (mm2) | 500*400~1800*1000 | 650*550~1000*2000 | 900*700~2000*1500 |

| Maximum weight of the box (Kg) | 1500~7000 | 3500~8000 | 3000~9000 |

Product process flow

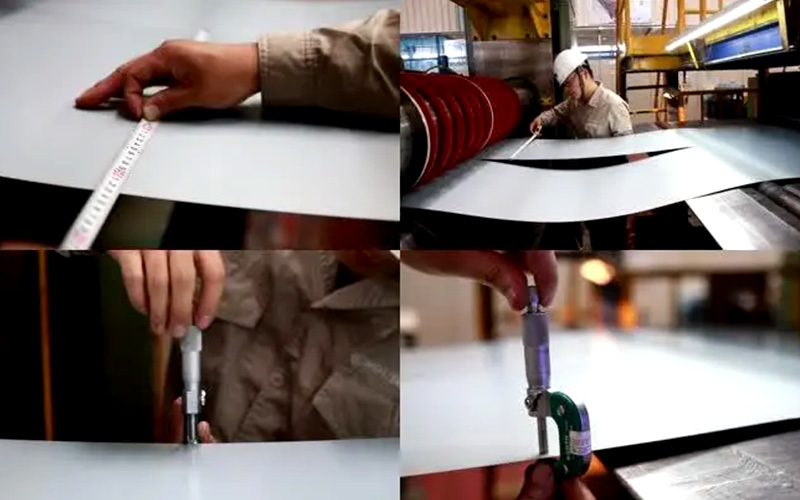

Incoming inspection

01

Cutting

02

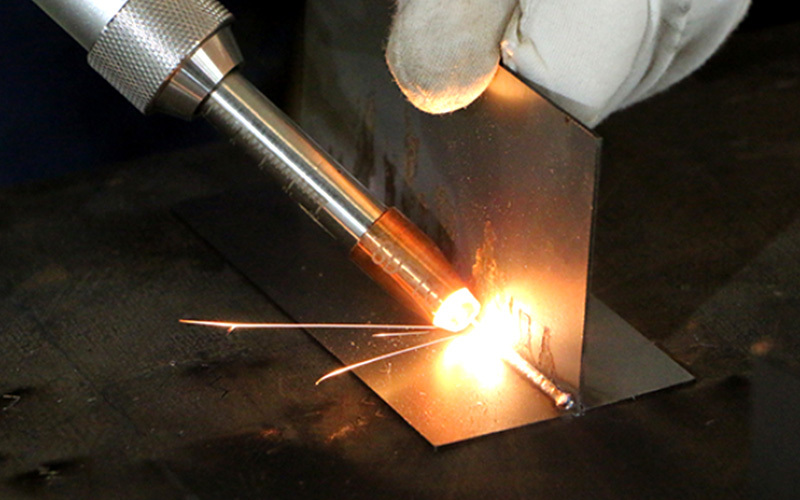

Welding

03

fine machining

04

Assembly

05

Initial debugging

06

Spraying

07

Packaging

08

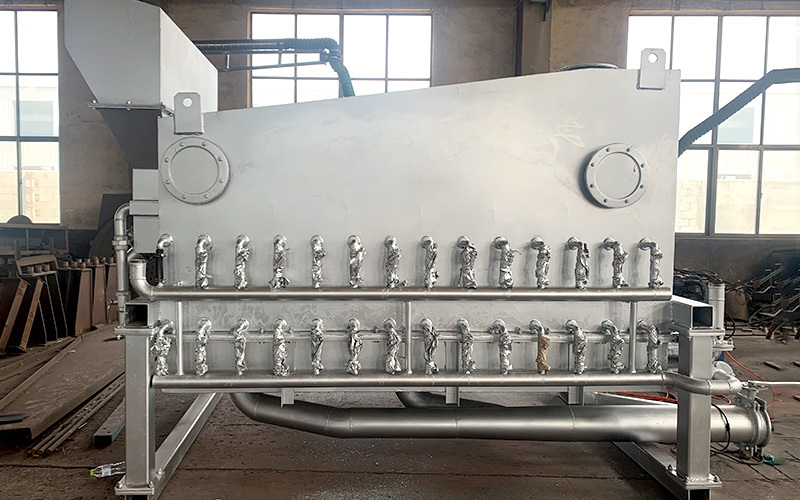

engineering case

Self-hardening resin sand sand treatment production line

China Yituo (Luoyang) Steel Casting Plant 120t-h Clay Sand Production Line

Rizhao Hongguan Machinery

Henan Zhongao Machinery 100t-h Clay Sand Production Line

V method, lost form production line

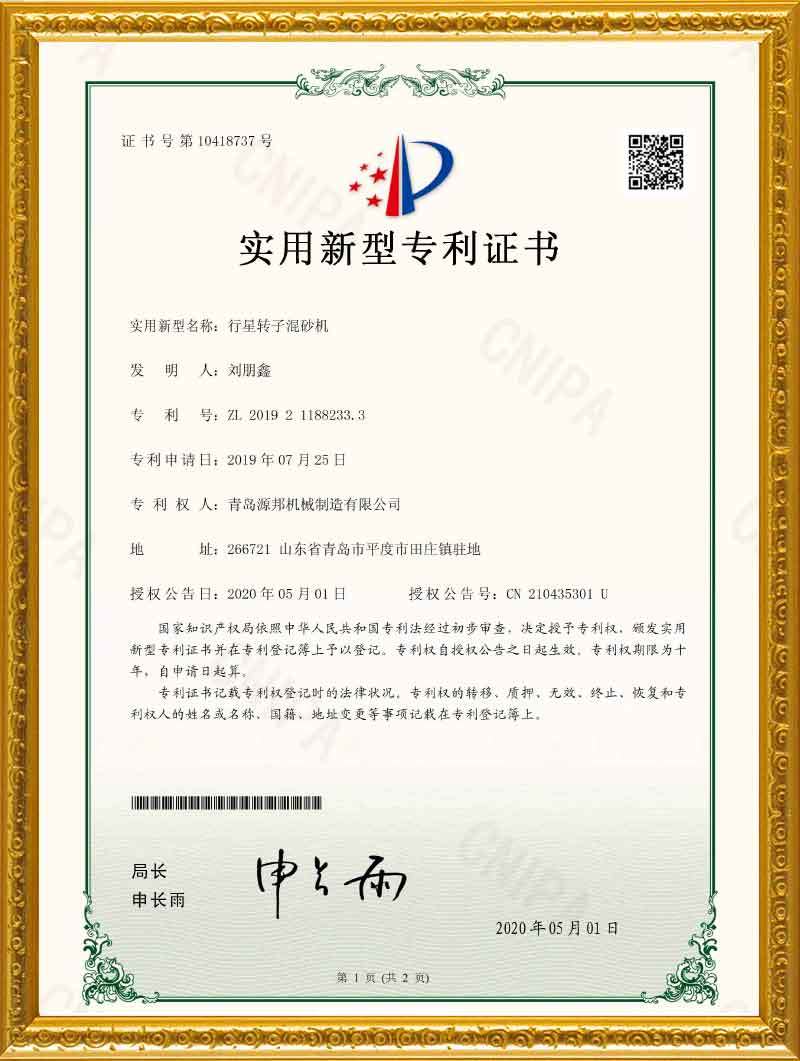

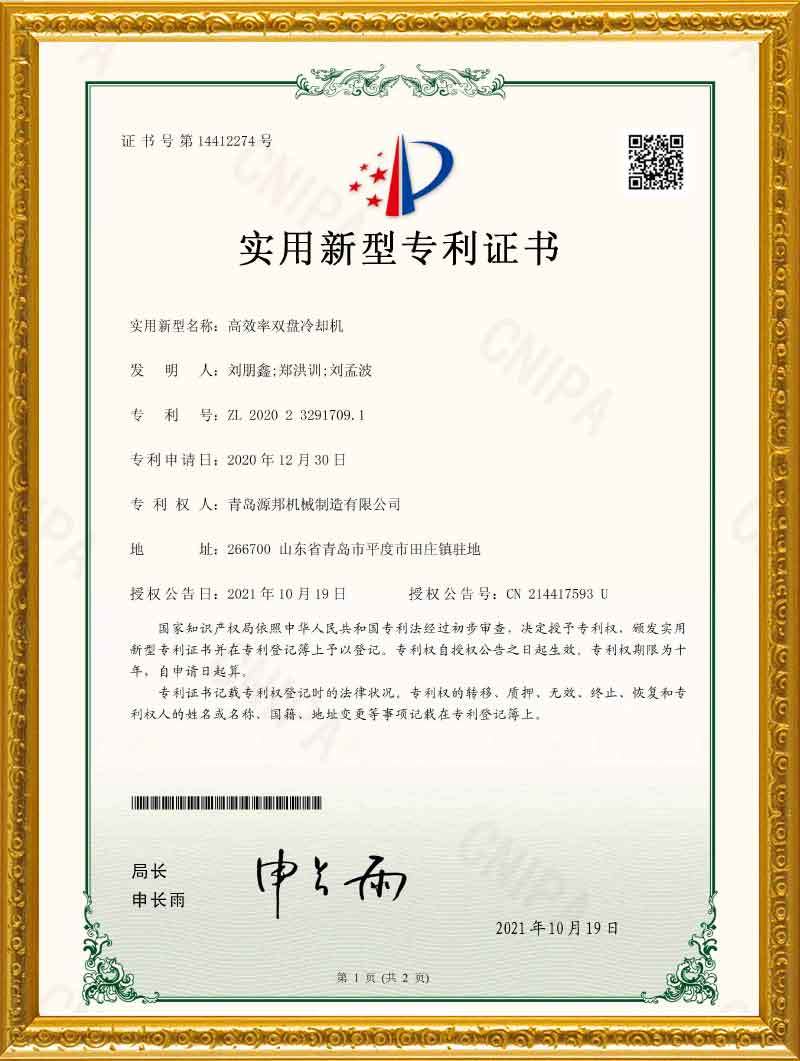

Honor

Related Products

2020/07/16

2020/07/23

2020/07/16

2020/07/16

SL Series Ebullated Cooling Bed Equipment

2020/07/16

S43 Series Fine Hexagon Sand Sieving Machine

2020/07/16

L32 Series Falling Sand Cooling Drum

2020/07/16

2020/07/16

Listen and provide trusted solutions.